Written by

Tony Hughes

Published

24 Feb 2023

Maximising Productivity & Cost Recovery Through Planning

This document is intended to serve as a guideline for maintaining the schedule with a focus on time related delays & disruption with emphasis on daily recording of project data for validation and substantiation of claims and identification of trends which can be analysed to enhance productivity in the field.

Tip 1. Why We Need to Rely on a Schedule for a Successful Commercial Outcome

Projects are supposed to be completed on time. Despite the best of efforts, delays situations arise that are often a condition not anticipated in the original contract.

In short, time related claims (extension of time, disruption or acceleration) are the acceptable processes for requesting adjustments for impacts to the project schedule. By implementing the appropriate processes and procedures the planners / schedulers can help to facilitate the early resolution of schedule related disputes and claims. The accuracy and completeness of the project schedule is important to the early and successful resolution of time related claims

When the schedule is properly developed, accurately maintained and supported by project documentation (basis of schedule, construction execution plans, commissioning plans, check estimates etc.) it is a vital element for successful resolution of time related claims. The Project Schedule should be utilised as a multi-functioning management tool that serves several purposes:

- For project planning and communication of the intent of that project plan

- To monitor progress and alert the project team to deviations from the plan

- To evaluate time impacts and focus on mitigation measures for timely completion

- To demonstrate entitlement to an extension of time

- To demonstrate entitlement to disruption (Measure Mile, Earned Value Analysis)

- To demonstrate entitlement to acceleration / constructive acceleration

- To provide a historic time record of what happened on the project

- To provide resource histograms for Construction, Safety and HR teams

Tip 2. Daily Project Planning and Data Collection for Early Warning of Delay & Disruption Events

The most important schedule for the project execution phase is the baseline schedule. However, the second most important schedule is the as built schedule when related to the successful resolution of claims.

Planners are responsible to provide and as built schedule that can be validated against project records to be used as an effective tool to facilitate the preparation for and / or defence of time related claims. The Contract terms and conditions generally address this requirement for both the main and supplier contracts.

The procedure for maintaining records of as-built facts that are verified through contemporaneous project documents is also important. An Early Warning Notice (EWN) if use effectively by the planning team can provide detailed information on delays and disruption to the planned work activities. To support the issues identified by the EWN and provide validation and substantiation of the facts, key documents Include:

Tip 3. Planners should plan their own day

To engage with other project disciplines, it is important that Planners are physically seen on the live construction site, furthermore adding value to the package team which includes management and trades. Visual interaction provides clear buy in between planning and construction in relation to schedule management and the use of the schedule as an effective tool to support the team. From experience, it is very rarely that a planner actual plans his or her own day, week or month. The illustration below is a sample that can be utilised by planning management on major projects.

| Time | Location | Activity | Description |

|---|---|---|---|

| 06:00 | Pre-Start | Pre-Start with package team | To identity planned activities for the day and any issues that may arise and / or package are performing reactive work activities |

| 07:00 | Office | Review of Pre-Start Notes | To review pre start planned activities against the baseline and look-ahead schedules and any issues with night shift |

| 08:00 | Office | General Planning | Updating schedules, what ifs, Review Logic based on Changed, Development of Look-ahead and Leve! 5 Detailed Planning for Complex Areas / Scope. |

| 09:00 | Office | General Planning | As above |

| 10:00 | Site Walk | First Site Walk | To identity if work is being conducted according to plan and pre start. Any issues need logged as an Early Warning Notice |

| 11:00 | Office | General Planning | Updating schedules, what ifs, Review Logic based on Changed, Development of Look-ahead and Level 5 Detailed Planning for Complex Areas / Scope. |

| 12:00 | Office | General Planning | As above |

| 13:00 | Office | General Planning | As above |

| 14:00 | Office | General Planning | As above |

| 15:00 | Site Walk | Second Site Walk | To identity if work is being conducted and progressing according to plan and pre start. any issues need logged as an Early Warming Notice |

| 16:00 | Office | Data Input | Data input Issues into Early warning Notice and Distribute to Relevant Parties superintendent, supervisor, Planning & Commercial Management |

| 16:30 | Office | Debrief with Package Team | Review of the planned activities and issues that have arisen during the day. |

Tip 4. Why we need to maintain a Schedule?

- Tracking progress by updating the project schedule on a weekly basis to assess actual performance against the plan.

- Assess impacts on the critical path and near critical activities and report critical work activities to the Area Manager/ Supervisor & Commercial Team. (Early Warning Notification for Basis of an Extension of Time Claim and if activities are not critical then can assist with a disruption claim).

A critical work activity is defined in several ways:

- An activity that is not meeting the required rate of production such that the project objectives will be met on or

- ahead of schedule.

- An activity that requires a resource allocation that is either unattainable or unmanageable.

- An activity whose late completion will delay the timely completion of a project objective.

- Assess impacts on non-critical activities (with float) and report (Early Warning Notification for Basis of a Disruption

- Claim) to Area Manager, Supervisor & Commercial Team

- Monitor schedule deviations and variances and assist in developing alternative methods for corrective action.

In summary, the weekly schedule update issue to Contractor should be reviewed for accuracy of reported progress and verification that there have not been any previously unreported changes.

Schedule narratives included in the weekly report need to address key resource assumptions underlying the schedule as well as changes that affect the critical path and changes that consume float, such as revised logic links or activity durations.

Furthermore, added / deleted and changed activity descriptions should be clearly explained to the project stakeholders. For prospective and retrospective forensic planning and delay analysis, a separate record of activities which started, finished, suspended or resumed in the week should be listed and reported to provide validation of as built dates.

Tip 5. Understand the Contract!

It is important for planners to understand the potential contract issues that are related to delay issues when developing, managing and controlling the project schedule. It is not enough to just create a ‘good working schedule’ the planner should also consider potential claims when building and maintaining the project schedule. For example, any obligation of the client to review a document should be added either as a task or milestone and logically linked into the work flow process.

With the above in mind, the planners should read and fully understand the project contract. The Contract should be seen as a rule book and generally contains a variety of time related clauses / articles / sub articles which may include:

- Ownership of Schedule Float

- Treatment of Concurrent Delay

- Contract Notification Requirements

- Definitions and Categories of Delays

- Schedule Change Management

- Acceptable Methods of Demonstrating Delay, for example – Time Impact Analysis (TIA)

Tip 6. What are the General Causes of Schedule Delay?

Planners need to know the probable causes of construction delays and extra work. Sources of delay issues that may impact a project are categorised below:

- Client / Owner / Operator Delays and Changes

- Engineering & Design Delays

- Contractor / Subcontractor / Supplier Delays and Changes

| Head Contractor / Owner / Operator | Design | Construction |

|---|---|---|

| Late Notice to Proceed | Defective Design / Contract Documents (drawings and tech specifications) | Poor Workmanship Requiring Rework |

| Lack of Site Access | Delayed or Incomplete Design | Insufficient Labour & Equipment |

| Lack of Laydown Area | Design Bulletins Resulting in Change Orders | Low Productivity |

| Administrative Delays | Untimely Responses to Requests for Information (RFI) | Insufficient Planning, Coordination or Management of the Work |

| Extended Submittal Reviews | Late Approvals / Extended Submittal Reviews | Delayed Administration of the Work (late subcontract and PO for award) |

| Funding Changes | Excessive RFI’s due to Incomplete Design | Delay in Processing Required Material & Equipment Submittals |

| Operator Enhancements | Excessive RFI’s due to Insufficient FEED information | Failure to Obtain Contract Approvals |

| Change Directives/Order | Unreasonable Inspections | Failure to Order Materials or Equipment in Time to Meet Schedule Requirements |

| Direct Suspension of Work | ||

| Delayed Free Issue Materials / Equipment | ||

| Delayed Performance by Client Contractors | ||

| Defective Contract Documents | ||

| Field Changes Required by Operational Team |

Tip 7. Implement an Early Warning Notice System

The Early Warning Notice procedure is an important management tool for the project in relation to time related delay and disruption data capture.

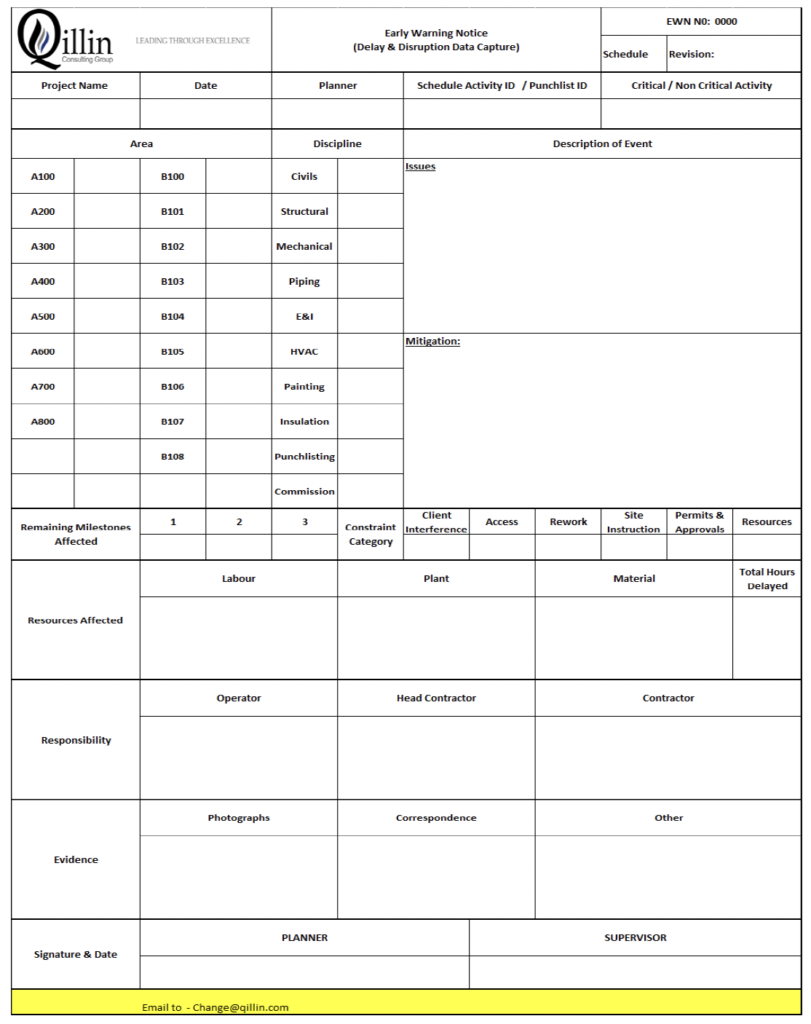

Sample Early Warning Notice (EWN) from Qillin.

Key aspect of the EWN is:

- Schedule Activity ID

- Critical / Non-Critical Activity

- Category Constraints

Schedule Activity ID

The Schedule Activity ID acts as unique identifier code in the P6 Database. By assigning the Activity ID to the EWN allows us to capture delay & disruption data which has impacted a specific activity.

Critical / Non-Critical Activity

Rule of thumb:

If an activity is critical, thus on the critical path, any subsequent delay would generally impact the Key Milestone dates. This would in theory give rise to an extension of time (depending on who is responsible) and prolongation costs.

If an activity is non-critical; thus, is not on the critical path, any subsequent delay which does not impact Key Milestone dates and thus not a critical delay could be carry forward and claimed as disruption. Generally, disruption is hard to prove unless there is a system in place i.e. EWN’s will document, record and date events, total number of resources impacted and who is responsible. If data is correctly inputted, each EWN can effectively be costed and submitted as a Change Order or back charge to supply chain.

Tip 7. Measurement of Planning Team – Key Performance Indicators

KPI’S are a set of quantifiable measures that the planning & senior management can use to gauge or compare performance in terms of meeting:

- strategic target of increased productivity within the planning team

- capturing data to support the as built schedule

- capturing data to support commercial outcomes (Early Warning Notice – EWN)

- ·increase planning team visibility in the project

- create solid, positive links and synergy between planning, commercial and construction departments.

Key Performance Indicators (Completed on Daily Basis)

- Attendance at Construction Package Pre-Start

- Morning Site Walk

- Afternoon Site Walk

- Attendance at Construction Package Debrief

- Early Warning Notice Submission

- Update of Early Warning Notice Register

In Summary, planners are accountable for improving the KPIs under their control. This provides them (and their management) with a yardstick to measure their performance. Not only does the planner have a way to quantify how he or she has contributed, but management can see which planners are contributing the most towards the team goals which in turn will be a key link in the overall project team strategy to enhance productivity and complete the project within budget.

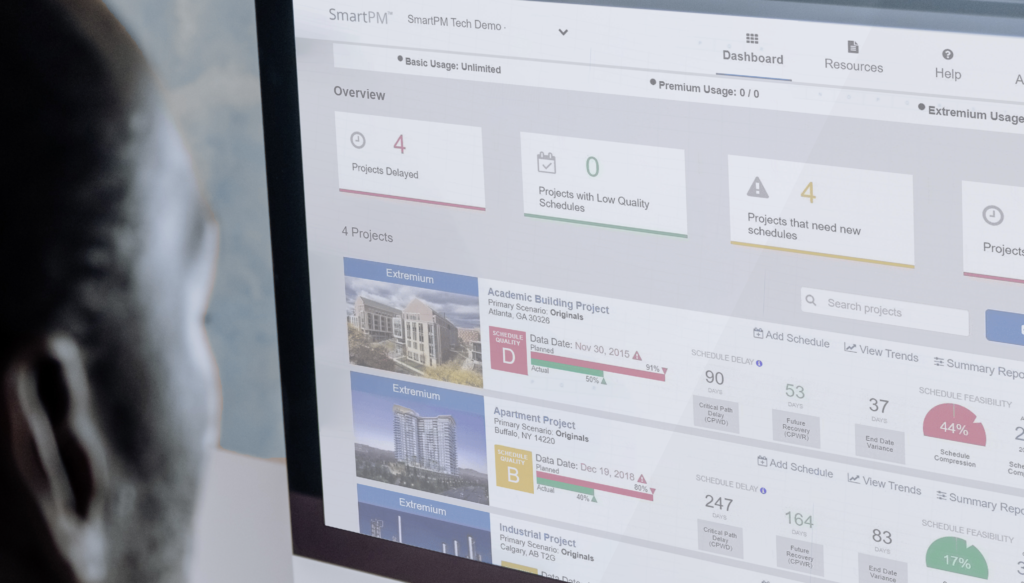

An off the shelf – KPI system can be run through a cloud based server supported by CDI Experts The software already has inbuilt dashboards, reports and analytics. Easy set up and easy to maintain

Written by CDI Experts Managing Partner Tony Hughes

Follow us for more!

Get the expert edge

Please add your details below and we’ll be in touch as quickly as possible